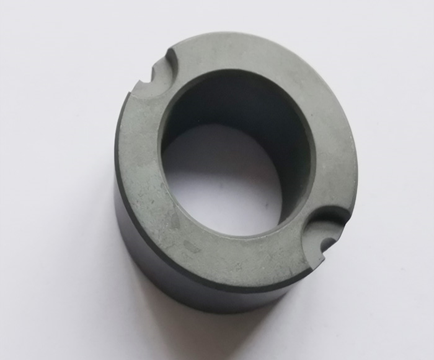

Special-shaped magnets Special-shaped magnets are called special-shaped magnets because their product shapes are not very conventional. Product shapes include: tile-shaped magnets, spherical magnets, square magnets, cylindrical magnets, and oversized ring magnets. The raw materials of product magnets are relatively brittle and the processing procedures are relatively complex. Mainly used in various machines, motors, wind turbines and other industrial purposes.

Compared with standard magnets, the most widely used special-shaped magnet materials are: neodymium iron boron and ferrite. Especially special-shaped machine electromagnetic tiles are one of the more common special-shaped magnets. Advantages of special-shaped magnets: The product is cost-effective and has good mechanical properties.

Special-shaped magnets have extremely high magnetic energy product and coercive force, and can pick up heavy objects equivalent to 640 times the weight of the product itself. It has been widely used in modern industry and electronic technology. The only shortcoming is that the product has a lower Curie temperature point and poor temperature characteristics. Easily powdered by radiation.

The product needs to be improved by increasing and adjusting its chemical composition and surface coating treatment to meet the requirements of actual use. Circular perforated ones, square perforated ones, square ones with corner/edge grinding, circular ones with stepped steps, and track-shaped ones. These are common special-shaped magnets, and the processing is relatively simple.